T Slots Tolerance

Slots with draft

If you are designing a ramp for a dog to get onto and off from the couch or a bed, you may use plastic sections with slots to snap the sections together.

A slot in a plastic molded part may have draft. This complicates how it should be dimensioned. Below is a best practice for how to dimension slots with draft.

The figure below shows our slot. Not only does it have draft, but it also has fillets and rounds.

If you are designing a ramp for a dog to get onto and off from the couch or a bed, you may use plastic sections with slots to snap the sections together.

A slot in a plastic molded part may have draft. This complicates how it should be dimensioned. Below is a best practice for how to dimension slots with draft.

The figure below shows our slot. Not only does it have draft, but it also has fillets and rounds.

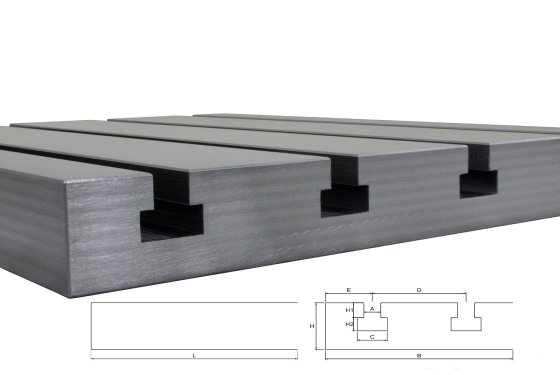

S e c na r e l o Tno i t ac9Lo 11 - 5 9.1 Position Tolerance 5-11 9.2 Concentricity & Symmetry Tolerances 5-13 10 Profi le Tolerance 5-14 11 Run Out Tolerances 5-18 12 Orientation Tolerances 5-19 13 Form Tolerances 5-21 13.1 Straightness 5-21 13.2 Flatness 5-23 13.3 Circulatity (Roundness) 5-23 13.4 Cylindricity 5-23 14 Conversion Charts 5-29. These plates have three T-slots for use with T-slot nuts, bolts, and setup studs. There is a slot along each side of the plate for mounting with clamps. Aluminum plates are lightweight and have mild corrosion resistance. Iron plates are heavy duty for long term use.

Below is our tolerancing scheme for our slot. It looks complicated, but it really is not. We will look at the tolerances one at a time.

We start with the goal of locating the the slot with a tolerance of position. Recall that a tolerance of position must be applied to a feature of size. That's easy if the slot has no draft. But our slot has draft. So we cannot define the entire slot as a feature of size. We need to pick a specific place in our slot to define as our feature of size. The top and bottom of the slot are not good places to define a feature of size because the top and bottom have corners that may or may not be sharp. This is why we go down a basic distance, a basic 10 in this case, from the top of the slot. This is where we will define our feature of size. Our size dimension says that at exactly 10 down from datum [A], the size must be 20 +/- 0.2.

Having established a feature of size, we can locate our feature of size with a tolerance of position. Our tolerance of position says that the center of our feature of size must fall within a 0.5 wide tolerance zone while holding the part on datum feature [A], and pushing it against datum features [B] and [C]. The slot is oriented to datums [A] and [B] and located to datum [C].

Everything we have looked at so far is specifically 10 mm away from datum [A]. Now we need to define the rest of the walls. We use a profile of a surface with a 0.1 wide tolerance zone. The profile of a surface does not locate the walls. They are located by the tolerance of position and the size tolerance. The profile of a surface controls the orientation and form. The profile tolerance zone will float within the size tolerance zone, and the profile tolerance zone will be exactly 99.5 degrees to datum [A] and exactly perpendicular to datum [B].

Finally we control the location, orientation, and form of the bottom of the slot with a profile of a surface that has a 0.5 wide tolerance zone. The tolerance zone is located and oriented to datum [A].

We start with the goal of locating the the slot with a tolerance of position. Recall that a tolerance of position must be applied to a feature of size. That's easy if the slot has no draft. But our slot has draft. So we cannot define the entire slot as a feature of size. We need to pick a specific place in our slot to define as our feature of size. The top and bottom of the slot are not good places to define a feature of size because the top and bottom have corners that may or may not be sharp. This is why we go down a basic distance, a basic 10 in this case, from the top of the slot. This is where we will define our feature of size. Our size dimension says that at exactly 10 down from datum [A], the size must be 20 +/- 0.2.

Having established a feature of size, we can locate our feature of size with a tolerance of position. Our tolerance of position says that the center of our feature of size must fall within a 0.5 wide tolerance zone while holding the part on datum feature [A], and pushing it against datum features [B] and [C]. The slot is oriented to datums [A] and [B] and located to datum [C].

Everything we have looked at so far is specifically 10 mm away from datum [A]. Now we need to define the rest of the walls. We use a profile of a surface with a 0.1 wide tolerance zone. The profile of a surface does not locate the walls. They are located by the tolerance of position and the size tolerance. The profile of a surface controls the orientation and form. The profile tolerance zone will float within the size tolerance zone, and the profile tolerance zone will be exactly 99.5 degrees to datum [A] and exactly perpendicular to datum [B].

Finally we control the location, orientation, and form of the bottom of the slot with a profile of a surface that has a 0.5 wide tolerance zone. The tolerance zone is located and oriented to datum [A].

The figure below shows the tolerance zone for the tolerance of position. The tolerance zone is two parallel lines that are 0.5 apart. The lines are exactly 10 down from datum [A]. They are exactly parallel to datum [A], and exactly perpendicular to datum [B]. The center of the tolerance zone is exactly 100 from datum [C]. The center of the slot, exactly 10 down from datum [A], must fall within the tolerance zone.

The figure below shows the size tolerance zone and the profile tolerance zone for the walls. The size is established only at exactly 10 down from datum [A]. The size tolerance establishes two 0.2 wide tolerance zones. Remember that the size tolerance zones are located to datum [C] by the tolerance of position callout in the figure above.

The profile tolerance zones can float within the size tolerance zones. Each profile tolerance zone is independent of the other one. Each profile tolerance zone is two parallel planes 0.1 apart, exactly 99.5 degrees from [A] and exactly perpendicular to [B].

The profile tolerance zones can float within the size tolerance zones. Each profile tolerance zone is independent of the other one. Each profile tolerance zone is two parallel planes 0.1 apart, exactly 99.5 degrees from [A] and exactly perpendicular to [B].

Finally we have the profile tolerance zone for the bottom of the slot. The tolerance zone is two parallel planes that are 0.5 apart. They are exactly parallel to datum [A], and the center of the tolerance zone is exactly 20 down from datum [A].

Our standard note says that the corners can range from sharp to 1 max radius, and now our slot is fully defined.

Standard metric T-slots and T-nuts

Standard Metric T-Slots

| Size | s1 (mm) | t1 (mm) | a1 (mm) | h1 (mm) |

|---|---|---|---|---|

| M4 | 5 | 10 - 11 | 3.5 - 4.5 | 8 - 10 |

| M5 | 6 | 11 - 12.5 | 5 - 6 | 11 - 13 |

| M6 | 8 | 14.5 - 16 | 7 - 8 | 15 - 18 |

| M8 | 10 | 16 - 18 | 7 - 8 | 17 - 21 |

| M10 | 12 | 19 - 21 | 8 -9 | 20 - 25 |

| M12 | 14 | 23 - 25 | 9 - 11 | 23 - 28 |

| M16 | 18 | 30 - 32 | 12 - 14 | 30 - 36 |

- 1 inch = 25.4 mm

Standard Metric T-Nuts

| Size | s2 (mm) | t2 (mm) | a2 (mm) | h2 (mm) |

|---|---|---|---|---|

| M4 | 5 | 9 | 2.5 | 6 |

| M5 | 6 | 10 | 4 | 8 |

| M6 | 8 | 13 | 6 | 10 |

| M8 | 10 | 15 | 6 | 12 |

| M10 | 12 | 18 | 7 | 16 |

| M12 | 14 | 22 | 8 | 19 |

| M16 | 18 | 28 | 10 | 25 |

Related Topics

- Fasteners - Bolts, nuts and threaded rods - torque, tension and loads

T Slots Tolerance

Related Documents

T Slot Tolerances

- ISO 724 - Metric Threads - Dimensions of metric threads according ISO 724

- Metric Bolt Head and Wrench Size - ANSI/SO, DIN and JIS bolts