5 Slot Vs 3 Slot Motor

Use an inside growler and test the stator assembly for shorted coils as instructed in TM 5-764 (Electric Motor. (3) Slot wedge.5-5-5 DMD-100 (36 pcs. Motor Slot online slot game by SkillOnNet has only high valued symbols. All of them are related to motorsports and shown with icons, such as traffic lights, security gloves, and skittles. Most awarding one is the race flag icon with 5.000 coins. Game has three special symbols only: Wild, scatter and bonus. Slot car motor products available at Professor Motor, Inc.

You currently have javascript disabled. Several functions may not work. Please re-enable javascript to access full functionality.

5 Slot Vs 3 Slot Motorcycles

Subforums

Havlicek's House of H-PowerForum for John Havlicek's amazing motor build threads. |

|

| Topic | Started By | Stats |

|---|---|---|

PinnedUnderstanding the evolution of the '16D' motorStarted by TSR, 22 May 2012 |

| |

PinnedArm winding #2Started by Cheater, 09 Jul 2013 |

| |

PinnedArm winding #1Started by havlicek, 05 Jul 2008Closed due to length |

| |

Professor Motor B52 ball bearing motorStarted by Tim Wood, 06 Mar 2019 |

| |

1/24 motor mounting pattern..Started by Revtor, 30 Jan 2021 |

| |

16D armature spacers - where to purchaseStarted by Lone Wolf, 29 Jan 2021 |

| |

Motor ID?Started by n.elmholt, 24 Jan 2021 |

| |

1965 Monogram Tiger Super X-88 12v DC motorStarted by Alchemist, 22 Jan 2021 |

| |

Armature sizesStarted by Horsepower, 16 Jan 2021 |

| |

Cleaning magnet dustStarted by Tim Wood, 13 Jan 2021 |

| |

Champion 507 restorationStarted by Isaac S., 07 Jan 2021 |

| |

Best fastest motors in orderStarted by ThunderThumb, 07 Jan 2021 |

| |

Champion 507RMC restorationStarted by Isaac S., 07 Jan 2021 |

| |

FT16DBB restoration with Arcos and Mura silver wire armStarted by Isaac S., 05 Jan 2021 |

| |

Mura 'Green Giant'Started by havlicek, 07 May 2013 |

| |

Champion 5001 restorationStarted by Isaac S., 04 Jan 2021 |

| |

Sealed D-can brush hood alignment toolStarted by Dave Person, 03 Jan 2021 |

| |

What's the deal with timing?Started by Isaac S., 02 Jan 2021 |

| |

Revtech slot car armaturesStarted by B.C., 15 Apr 2017 |

| |

Champion Super WaspStarted by YetiSRP, 31 Dec 2020 |

| |

Assembling aluminum endbellsStarted by mreibman, 28 Dec 2020 |

| |

What is a VR motor?Started by Rotorranch, 08 Dec 2020 |

| |

Old time armature guysStarted by Jesse Gonzales, 06 Dec 2020 |

| |

JK Products Hawk motor balancingStarted by Cheater, 04 Dec 2016 |

| |

Five and seven pole winding patternsStarted by Gator Bob, 02 Mar 2015 |

|

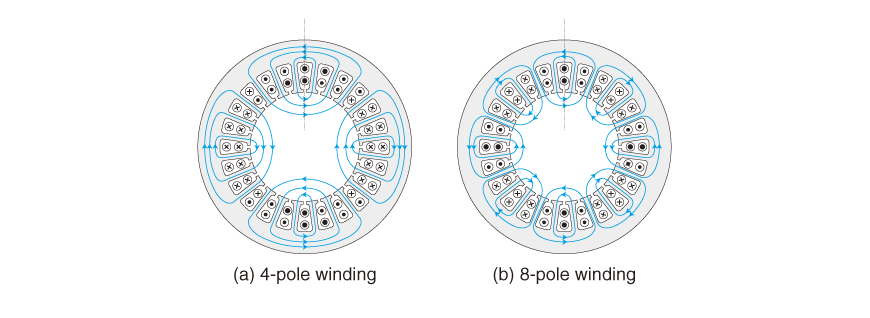

The original brushless DC (BLDC) motors were designed with slotted stators, and the majority of BLDC motors are still made this way. But this design produces cogging torque, which makes it difficult to achieve smooth motion, especially at slow speeds. To eliminate this effect, a new design was developed, eliminating the slots in the stator (which are the root cause of cogging torque), and slotless motors were born.

In a slotted motor design, the stator is made of slotted steel laminations that are stacked together, and copper windings are inserted into these slots. (The design of the stator is sometimes referred to as having “teeth.”) The slotted motor design is simple and inexpensive to manufacture, but it has a major drawback—cogging torque. Cogging torque (also referred to as “detent torque”) is a result of the permanent magnets in the rotor attempting to line up with the slots, or teeth, of the stator. The primary effect of cogging torque is that it causes motor rotation to be jerky (not smooth), especially at low motor speeds.

The term “iron core” is commonly used when discussing slotted linear motors. This originates from the fact that the assembly of stator windings encased in a steel, slotted stator is sometimes referred to as an “iron core.” Slotless linear motors, on the other hand, are often referred to as “air core” motors.

5 Slot Vs 3 Slot Motorcycle For Sale

In a slotless motor, there are no iron teeth to support the windings. Instead, the stator lamination is constructed of steel rings that are stacked together, and the windings are encapsulated in an epoxy resin, which gives the winding structure shape and rigidity. This “self-supporting” winding is placed in the air gap between the stator lamination and the rotor.

5 Slot Vs 3 Slot Motor

The primary benefit of a slotless motor design is that the lack of teeth in the lamination eliminates cogging torque and results in a motor with very smooth running characteristics. Torque production is predictable and highly controllable, because in the absence of these uncontrolled disturbances (i.e. cogging torque), motor torque production is directly related to the current supplied to the winding.

There are other benefits to the slotless design. First, the elimination of cogging also significantly reduces audible noise. And since there’s no iron core, inductance is very low and current can get into the stator windings very quickly, making slotless motors good for applications that require high acceleration and dynamic response.

But slotted motors still hold some advantages. For example, the air gap in a slotted motor is smaller than the air gap in a slotless design (which must accommodate the self-supported winding assembly). This means that the flux density is higher in a slotted motor, and torque production is more effective and efficient.

One way that manufacturers of slotless motors overcome the effects of the bigger air gap is to use larger, stronger permanent magnets in the rotor. But this increases cost. And, the cost to manufacturer the self-supporting winding structure is typically higher than a conventional slotted design. For this reason, the traditional slotted motor design is still the first choice for applications in which smooth running and the elimination of cogging are not critical.